Pipeline pressure sensors are an extremely important device in measuring and controlling pressure in pipeline systems of oil, gas, water, chemicals, fuel, etc. They sense the price pressure value and convert from mechanical signal to electrical signal, then transmit electrical signal to display or control device, PLC or warning device,… In today’s article, Makgil Vietnam would like to invite Readers join us to learn the necessary information about this type of pressure sensor.

What is a pipeline pressure sensor?

Pipeline pressure sensors (also known by many other names such as pressure sensors, pressure sensors, pipeline pressure sensors, pipeline pressure sensors, pipeline pressure sensors,…) are called In English, Pressure Sensor (or Pressure Transmitter, Pressure Transducer) – is a measuring device with the function of measuring and controlling the pressure value in oil, gas, water, chemical or raw material pipelines, fuel, etc. They perform the function of receiving pressure values in mechanical form and converting them to electrical signals, then transmitting electrical signals to display devices (such as display screens), warning devices ( warning bell, siren,…), PLC or control device (pump control, valve,…).

The output signal of a pipeline pressure sensor is usually in three forms: mV form (0-5 mV, 0-10 mV, 10-30 mV,…), voltage form (0-5V DC, 0-10V DC ,…) or analog signal form (0-20mA, 4-20mA). We can easily see pipeline pressure sensors in many places, especially in industrial factories.

Structure and operating principle of pipeline pressure sensor

1. Structure of Pressure Sensor

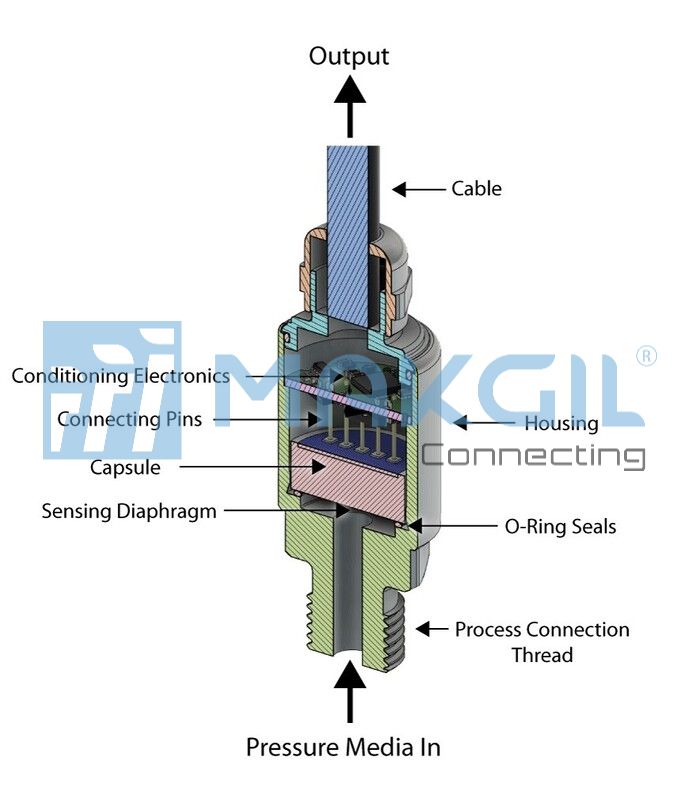

Pressure Sensors are divided into many different types, depending on the classification criteria. However, basically a pressure sensor usually consists of the following main parts:

- Sensor body (Body): Is the entire mechanical part that covers the outside of the sensor, protecting the elements inside the sensor from external influences. The body of the sensor is usually made from stainless steel SS304/SS316 or other special materials in specific cases.

- Mechanical connection (Process connection): Pressure sensors usually have three basic connection types: threaded connection, membrane connection and clamp connection, in which threaded connection is the most common connection type. This is the bottom part of the sensor, which has the function of connecting and sealing the sensor with the pipe.

- Sensing diaphragm: Is the part located inside the body of the sensor, right above the mechanical connection, which senses the pressure value from the medium and transmits it to the capsule above. In addition, the sensor membrane only accepts mechanical pressure values, while not allowing the medium to pass through and damage the electrical elements above.

- Sealing parts (O-ring Seals): Usually made from some material such as rubber or a variation of rubber, with the function of sealing the contact between the sensor membrane and the inside of the sensor body, preventing The medium passes through the membrane and comes into contact with electrical parts, causing damage.

- Sensor part (Capsule): Is the part located on top of the sensor membrane, with the function of receiving signals from pressure and transmitting signals to the processing part. Depending on the type of sensor, it converts from a mechanical signal of pressure to a signal of resistance, capacitance, inductance, current… to the processing unit.

- Processing unit: has the function of receiving signals from the sensor and performing processing to convert those signals into standard signals such as 4 ~ 20 mA output signals (commonly used signals). most commonly used), mV signal or voltage signal.

- Cable Connection: Located at the top of the sensor, is the electrical cable that receives signals from the processing unit and transmits them to display, warning or control devices, etc. Depending on the design or At the customer’s option, the end of this connection cable may or may not have a protective tip (usually made of plastic).

2. Operating principle of pipeline pressure sensor

All types of pipeline pressure sensors operate on the same principle. When the pressure source acts on the sensor’s membrane (this measuring membrane is often implanted on piezoresistive elements), the sensor sends the value to the microprocessor, then the microprocessor is responsible for processing the signal. transmitted to the display device (if the user only has the purpose of displaying the pressure value), warning device or control device, PLC, from which the warning or motor control operates.

Technical specifications of pipeline pressure sensor from ESI-TEC/UK

Currently, there are many pipe pressure sensor brands on the market, each brand has different design parameters. Below, we would like to mention the basic parameters of the ESI-TEC pressure sensor that we are distributing, a brand from the UK with excellent quality, possessing the most advanced measurement technology. world and is used in many countries.

| Measuring range: | Up to 5000 bar (equivalent to 72,000 psi) |

| Output signal: | 10 mV/V (4 wire), 0 – 5 V (4 or 3 wire), 0 – 10 V (4 or 3 wire), 4 – 20 mA (2 wire),… |

| Power supply: | 10 VDC (5 – 15V), 13 – 30 VDC, 10 – 36 VDC,… |

| Sensor technology: | Silicon-on-Sapphire (SoS) |

| Overvoltage safety: | Up to 1.5 times full scale (other brands are usually 1.2 times) |

| Accuracy level: | ≤ ±0.1 % or ≤ ±0.25 % (optional) |

| Working temperature: | -50°C to +125°C (or optionally up to +400°C) |

| Response time: | 1 mS (extremely fast, other brands are typically 10mS) |

| Certificates: | ATEX/IECEx, DNV GL, CE |

| Vật liệu màng: | Alloy Titan (đối với dải đo ≥1,000 bar) Titanium alloy và SAE 316 stainless steel (đối với dải đo <1,000 bar) |

| Mechanical connection: | G1/4, G1/2, ½” NPT, ¼” NPT (or according to specific requirements) |

| Origin: | United Kingdom (UK) |

| Warranty period: | Minimum 18 months |

Some necessary criteria when choosing a pipeline pressure sensor

Currently, many people find it difficult to distinguish between different types of sensors and choose to buy the right sensor. Therefore, when choosing to buy a pressure sensor, we need to pay attention to the following points to choose the right sensor to use and bring the most efficiency.

- Fluid to be measured: Users need to determine whether the medium they will use, for example measuring pressure for water, seawater, steam, oil, chemicals, fluids with viscosity or residue… From here Determine suitable materials and sensor types.

- Measuring range: Users need to determine the maximum pressure, then select the appropriate pressure range. Basically, users should choose a measuring range higher than 30% of the maximum operating pressure to ensure the sensor has high durability, avoiding overpressure cases that damage the sensor.

- Unit of measurement: commonly used units of measurement for pressure sensors are bar, kgf/cm2, psi, mH2O, etc. Users should determine the appropriate unit of measurement to facilitate observation and monitoring.

- Connection type: Users need to determine the connection type to suit the pipe/system/equipment installed with the sensor. Three common connection types are threaded connections, network connections or clamp connections.

- Allowable error: Users need to determine the allowable error and overpressure tolerance.

- Output signal: Users need to determine the output signal that suits their needs. Three common output signal types are 4-20mA, mV or V signals.

- Working temperature: Users need to determine the working temperature of the medium, thereby determining the type of sensor with the appropriate design temperature. Normally, in some applications where the temperature is higher than the sensor’s design temperature, we need to use heat-reducing accessories for the pressure sensor such as a siphon tube to protect the sensor from being damaged due to higher temperatures. permitted levels.

Makgil Vietnam – Supplier of genuine pipeline pressure sensors, made in Europe

Makgil Vietnam is one of the most experienced units in the field of supply and installation of pressure and temperature measuring devices in the Vietnamese market, including pipeline pressure sensors. With many years of experience in the industry, Makgil is currently an authorized distributor of ESI-TEC/UK and WIKA/Germany – two European countries famous in the measurement industry with world-leading quality and technology. gender. With a team of experienced staff, we can also easily advise customers on choosing the right type of pressure sensor to suit their requirements and purposes, with the most optimal and reasonable cost. . In particular, with a very large volume of goods in stock with a full range of types, measuring ranges, materials, sizes, and prices, Makgil Vietnam always commits to being the best in the market, with a minimum warranty period of 18 months, ensuring Guaranteed so customers can choose with confidence. Customers please note that we do not provide goods originating from China, with Chinese brands, affecting our reputation and the safety of users’ systems. Makgil Vietnam is pleased to serve all customer requests according to the detailed information below: MAKGIL VIETNAM COMPANY LIMITED Head office: 18/21 Nguyen Van Dung, Ward 06, Go Vap District, City. Ho Chi Minh Hanoi Branch: No. 130 D4 Dai Kim New Urban Area, Dai Kim, Hoang Mai, Hanoi Phone: 02866-572-704 Fax: 02822-026-775 Website: https://makgil.com Email: info@makgil.com Zalo: 0902 949 401 – 0902 988 005 – 0932 798 882